Have you ever wondered how implementing a SCADA system can transform the productivity and efficiency of your industrial plant? In a world where Industry 4.0 and Industrial IoT are the new norm, adopting a SCADA system can seem overwhelming. Technical challenges, integration with existing systems, and cybersecurity are often critical points, but with the right tools and approach, these issues become opportunities to optimise every aspect of your operation. Want to know how to achieve this? Keep reading.

Main Challenges in Implementing SCADA Systems

Implementing SCADA systems is not just about acquiring technology; it involves a strategic process to ensure that every component of your plant operates in synergy. Below, we explore the main obstacles that may arise during this implementation and why it is essential to address them with specific solutions.

Integration with Existing Systems

In modern industrial plants, there is already a wide range of devices, sensors, and legacy systems that perform essential functions. However, connecting all these elements to a SCADA system can be a significant challenge. Compatibility between old and modern technologies requires flexible solutions and communication standards to ensure efficient integration. If not managed properly, this challenge can lead to operational disruptions, data loss, and increased maintenance costs.

Scalability

Scalability is an aspect often overlooked in the early stages of SCADA system implementation. Industrial plants are constantly evolving, and failing to plan for a system that can grow with the business needs can cause long-term problems. A system that is not scalable may require costly upgrades or even complete replacement. Having a solution designed to adapt to the growth of your operation is key to ensuring its future success.

Cybersecurity

In the era of Industrial IoT, connecting devices and systems to the internet brings great opportunities but also significant risks. Cyber threats can compromise critical data and halt operations, resulting in high costs and reputational damage. The lack of robust cybersecurity strategies during the implementation of a SCADA system can expose vulnerabilities that attackers may exploit.

Learning Curve and Adoption

Technology is only as effective as the people who use it. If the operational staff do not receive proper training or if the SCADA system has a complicated interface, its adoption can be slow and inefficient. This not only reduces initial productivity but also affects team morale, leading to less successful implementation.

Effective Solutions for Implementing a Successful SCADA System

Implementing a SCADA system in industrial environments presents challenges ranging from integrating multiple devices to security and user experience. To ensure efficient and hassle-free adoption, it is crucial to choose a solution that offers interoperability, flexibility, security, and ease of use.

atvise® SCADA positions itself as an ideal option, as it combines pure web technology with native OPC UA support, making it an advanced platform for monitoring, control, and analysis of industrial data. Below, we explore the keys to successful implementation and how atvise® addresses these challenges.

Smooth Integration Thanks to the OPC UA Standard

One of the biggest obstacles in SCADA implementation is integration with different devices and systems, especially when they come from different manufacturers. The lack of compatibility can generate additional costs and increase project complexity.

atvise® SCADA is natively developed on OPC UA, the most advanced open standard for industrial interoperability. This allows easy connection of devices, PLCs, databases, and third-party systems without the need for additional developments or proprietary middleware.

Modern Visualisation Solutions for Flexible Operation

In the era of industrial digitalisation, mobility and remote access have become essential requirements for any SCADA system. However, many market solutions still rely on traditional client-server software, limiting the system’s accessibility and flexibility.

atvise® SCADA is based on pure web technology, meaning it does not require additional software or plugins to run. It is accessed directly from any web browser on PCs, tablets, and smartphones, allowing full control from anywhere, at any time.

Enterprise-Level Security

With the growing connectivity of SCADA systems, cybersecurity has become a priority. Cyber threats can compromise data integrity and jeopardise the operability of critical facilities.

atvise® offers advanced security based on OPC UA, with user authentication, data encryption, and multi-level access control. Additionally, its web-based architecture facilitates the implementation of HTTPS protocols and VPNs for secure communication.

Optimised User Experience

One of the key factors for the success of a SCADA system is usability. Complex interfaces, lack of customisation, or unintuitive visualisations can hinder adoption by operators, reducing system efficiency.

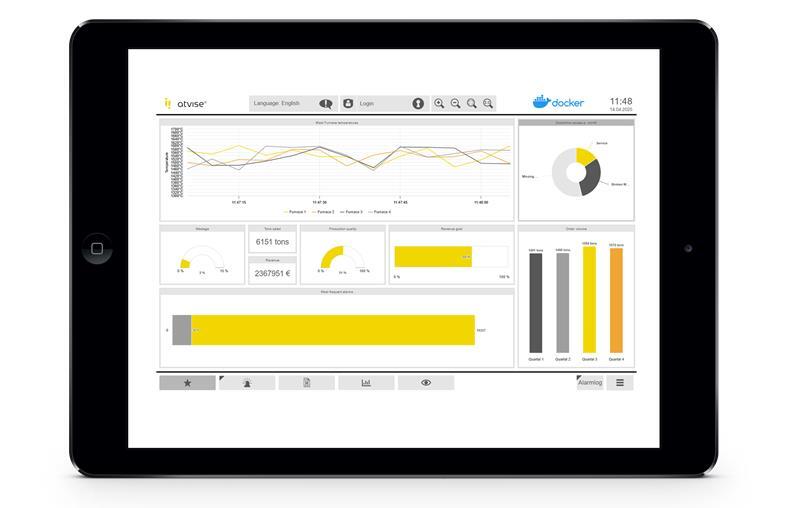

atvise® stands out for its powerful graphics engine based on vector graphics and its Dashboard library for data analysis. Furthermore, its responsive interface adapts to any device, ensuring an optimised user experience.

Key Benefit: atvise® allows the creation of customised interfaces with intuitive dashboards, interactive graphical representations, and agile navigation, facilitating real-time process monitoring and control.

Why atvise® Is Your Best Ally for Implementing This Type of Application

Implementing a successful SCADA system involves overcoming technical, security, and usability challenges. atvise® SCADA, with its pure web technology, native OPC UA support, and focus on security and user experience, offers a comprehensive solution for modern industrial environments.

If you are looking for a scalable, flexible, and secure SCADA, atvise® is the best option to optimise the monitoring and control of your industrial processes.

Are you ready to take the next step towards the digital transformation of your industry? Discover how our solutions can help you achieve a higher level of productivity and profitability. Request a free demo and start transforming your industrial plant today.