Can you imagine a world where factories not only produce faster but also in a more efficient and sustainable way? Smart factories are paving the way towards this reality. In a global economic environment that demands constant innovation and resource optimisation, these factories have evolved from a futuristic concept to a strategic necessity. But what makes them so special? In this article, we will explain how these facilities are transforming the global economy and why they are at the core of Industry 4.0.

What Are Smart Factories?

The concept of smart factories refers to highly automated and connected manufacturing facilities, where every machine, system, and process operates in synchronisation thanks to the integration of advanced technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), and real-time control systems. But beyond technology, smart factories are defined by their ability to rapidly adapt to market demands, maximising efficiency and minimising errors.

Key Features of a Smart Factory

- Real-time connectivity and communication: Through IoT sensors and devices, smart factories continuously collect and process data, enabling decision-making based on up-to-the-second information.

- Advanced automation: With AI and machine learning algorithms, many repetitive tasks are performed by machines, freeing up workers for more strategic and creative roles.

- Adaptability and flexibility: These factories can adjust their production almost instantly, whether to meet a customised order or to respond to sudden market demand changes.

- Sustainability as a priority: By monitoring energy consumption and optimising resource usage, smart factories are not only more profitable but also more environmentally friendly.

- In summary, a smart factory is far more than just a production facility; it is a dynamic ecosystem that integrates technology, data, and people to achieve ambitious business goals.

Main Benefits of Smart Factories

The impact of smart factories extends beyond internal company results. These innovations are driving significant transformations in the global economy. Here’s how and why they are so relevant:

Increased Productivity

One of the biggest challenges in traditional factories is efficiently managing time and resources. With smart factories, this is no longer a problem. By automating repetitive processes and optimising operations through advanced monitoring systems, companies can achieve unprecedented productivity levels. For example, by detecting issues in real time, machines can automatically adjust to prevent disruptions, resulting in a smoother and more consistent production flow.

This increase in productivity benefits not only individual companies but also local economies, enhancing their export capacity and competitiveness in the global market.

Reduced Operational Costs

The ability to predict and prevent equipment failures is one of the most notable advantages of smart factories. Thanks to real-time data analytics, preventive maintenance can be carried out, significantly reducing costs associated with unexpected downtimes. Additionally, energy and material usage is optimised, generating substantial long-term savings.

For example, in a smart factory, sensors can detect when a machine is consuming more energy than usual, allowing the issue to be corrected before it becomes a major expense. This not only improves efficiency but also contributes to the company’s financial sustainability.

Greater Environmental Sustainability

In a world increasingly concerned about climate change and carbon footprints, smart factories are key allies in achieving a more sustainable economy. Their ability to monitor and optimise resource usage reduces waste, while the incorporation of renewable energy sources in their processes minimises environmental impact.

On a macroeconomic level, this means that countries adopting these technologies can lower their industrial emissions and meet international sustainability targets, improving their global reputation.

Continuous Improvement in Product Quality

Quality is a critical factor in remaining competitive in the global market, and smart factories excel in this area. By integrating advanced systems such as SCADA Web atvise®, these facilities can conduct quality checks at every stage of the production process, ensuring that products meet the highest standards.

This benefits not only consumers, who receive reliable and high-quality products, but also companies, which strengthen their brand image and expand into new markets.

Smart Industries: The Bridge to Industry 4.0

At Vester, we understand that transitioning to a smart industry is not just an option but a necessity for companies aiming to stand out in the Industry 4.0 era. That’s why our innovative solutions can transform your industrial plant into a powerhouse of productivity and profitability.

How Can atvise® Help You?

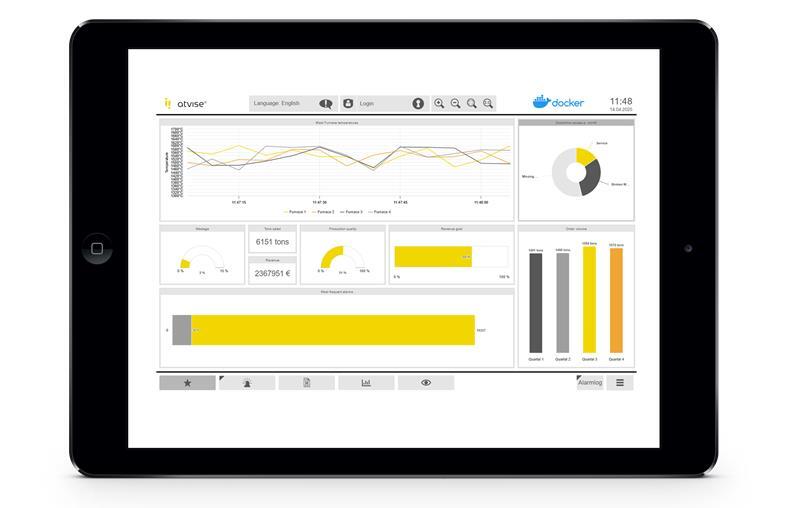

- SCADA Web System: Monitor and control your plant in real time from anywhere and any internet-connected device.

- OPC UA Protocol: Seamless integration of all your systems, ensuring reliable and efficient data exchange.

- Multi-platform SCADA: Our system operates on any device, regardless of the operating system, adapting to your needs.

- 100% Online SCADA Engineering: The engineering tool offers secure remote configuration, reducing installation costs and time.

As part of our mission, we work with you to maximise your plant’s performance, helping you reach new levels of efficiency, quality, and sustainability. We know that each industry faces unique challenges, and our solutions are designed to address them effectively.

In summary, smart factories are redefining the global industrial landscape, becoming the central pillar of a more productive, sustainable, and competitive economy. Adopting these technologies is not just an investment in the future but a key strategy for ensuring long-term success.

Are you ready to be part of this revolution? Find out how we can help you—request a free demo today!