Smart Factories: Present and Future of Industry

Manufacturing processes known 20 years ago, have become obsolete. Technology advances to help us refine the production process, and it is from this innovation that the concept of smart factories comes from. Relying on new technologies, the industry has evolved to offer more efficient and stable solutions to limits never before known… Do you want to know how smart factories work?

What is a smart factory?

A smart factory can be defined as that factory that applies automatisms (technology) in its production process in real time. This allows the factory to adapt to the changing conditions of the industrial environment, to establish a flexible production model and above all to increase the efficiency of industrial machinery. All the elements of the factory are connected to each other by systems such as SCADA, which allows an operator to supervise that all scheduled processes are fulfilled correctly.

Advantages of a smart factory VS Conventional factory

One of the main advantages of a smart factory is that it is able to accommodate its production level by adapting to changes in demand and market changes, something that a conventional factory is not able to do. In addition, they are also able to minimize the amount of waste that is generated in their production process by not trying to produce more than the market demands.

In a conventional factory, one of the main functions is the efficient management of resources. This efficient management of resources is an inherent feature of a smart factory, but it is not the only benefit obtained from developing a smart factory.

Smart factories are able to produce the items that are being demanded in the market, thus eliminating the product waste that is generated when conventional factories produce at more capacity than market demand.

For these reasons, we are finding more and more smart factories in the industrial market and conventional factories are disappearing.

Key elements in smart factories

Podemos identificar 6 componentes que hacen que la fabricación inteligente sea posible hoy en día:

We can identify 6 components that make smart manufacturing possible today:

IIoT applied to the industrial sector

The IIoT is responsible for the interconnection of industrial devices through the network, therefore, it is the subset of the Internet of Things that is dedicated exclusively to industrial production.

Cloud Computing

Cloud computing involves running programs or applications on an external server connected over a network. It allows us to cross data processed by different machines or industrial elements.

Autonomous systems

An autonomous system is a group of networks with their own independent policy, managed by one or more operators. In other words, it’s like the internet, but on a small scale. It is usually used in the industrial sector to create secure computing environments in case of leaks or cyberattacks.

Cybersecurity

When processing data in the cloud or being connected to the internet, we run the risk of receiving attacks in our smart factory. To avoid serious problems in our production process, it is necessary that we establish a series of practices, processes and security protocols that guarantee the security of the entire system.

Universal integration

In a smart factory it is common for us to find different types of technologies that make it difficult to interact with each other. For this reason, Industry 4.0 is moving towards a universal integration that allows seamless communication between machines, devices, systems and software applications. The best technology to achieve this full interoperability is OPC UA.

Big Data

Big Data applied to the industrial sector is what allows us to move from a conventional factory to a smart factory. One of the main advantages of Big Data is to manage all the data, combine them and process them to set actions to execute by machines in real time.

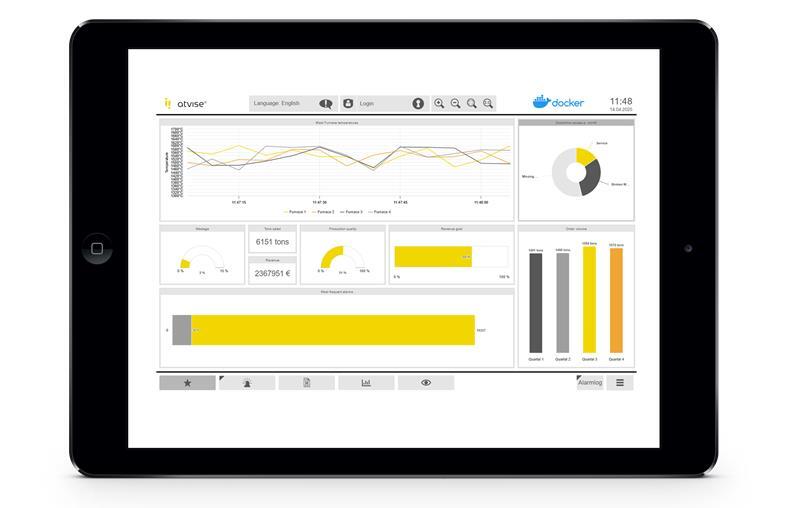

DISCOVER atvise® SCADA

atvise® SCADA is adaptable to any type of industry and sector, allowing you to run live reports and visualize past actions and future actions through the predictive capacity system that it implements in its core.

Using Big Data in a Smart Factory (How is it used?)

Big data is used to analyze large volumes of data in order to detect subtle patterns, useful for improving the production efficiency of a company. It is also known as Artificial Intelligence (AI): from the data collected in a company, mathematical models can be created to get future predictions based on past events. It is a powerful tool that allows industries to adapt to the rapid changes occurring in the market.

Application of artificial intelligence (AI) in a smart factory. (How is it used?)

AI is applied in the production processes of an industry to detect and correct errors, optimize production processes, reduce costs and, above all, increase productivity. An AI tool analyzes all the data that a company receives on a daily basis and, based on this, generates a prediction of how the production variables will develop in the future.

Companies can not only use data to detect errors, but also to analyze the entire flow of production and detect downtimes, so artificial intelligence is necessary. For example, data collected in a treatment plant can be analyzed to detect common points in those processes that are lacking or delaying the production flow.

Difference between Big Data and IoT

Big Data and the Internet of Things (IoT) are two terms that, at first glance, do not seem to have much to do with it. However, both are very powerful tools that, combined, can improve the efficiency of a company. The difference is that big data is a tool used to analyze large volumes of data and use artificial intelligence to generate mathematical models that predict the future. On the other hand, IoT is a technology that allows machines and infrastructures to be connected to interact with each other, even when they are at very large distances.

If you want to know how to apply these technologies in your production process and develop a smart factory, in Vester Business we have the best professionals to advise you on the choice of your software.