If you have worked in the automation industry, you’ve probably heard of HMI systems. Well, in this article we are going to discover all the secrets of this system and its features. Are you ready? Let’s dive in then!

What is an HMI system?

An HMI (Human Machine Interface) system is a user interface that allows a machine to communicate with a human being. With the use of an HMI system, communication between the machine and the operator is facilitated, so that the operator can execute their tasks correctly with greater comfort and in a faster way.

It is a system that allows us to interact with the machine, with the process, with the information, with the operation, with the industry, with the people, etc. In addition, it allows us to fully control the information, that is, the data we want to receive. Also, it allows us to interact with the processes in a simpler way, through an interface that is the screen.

HMI System: Main functions

An HMI system will allow us to manage in a more efficient way our needs as well as the needs of our customers. Considering that this system is one of the most important factors for a process to work:

Who can use an HMI system?

The platform we use is very advanced technology, easy to use and will allow anyone, regardless of their area of work or specialization, to achieve a perfect result. It is easy to use because, despite being a very advanced technology platform, it has a clear and easy to understand interface for an operator.

Requirements for HMI Systems

Every HMI system must be connected to a machine, it can be a machine programmed to operate automatically or a machine programmed to operate under the intervention of a person. In the first case, the machine must have a control interface, usually fieldbus or serial bus. In the second case, the machine must have signal outputs or control contacts that can be controlled from the HMI system.

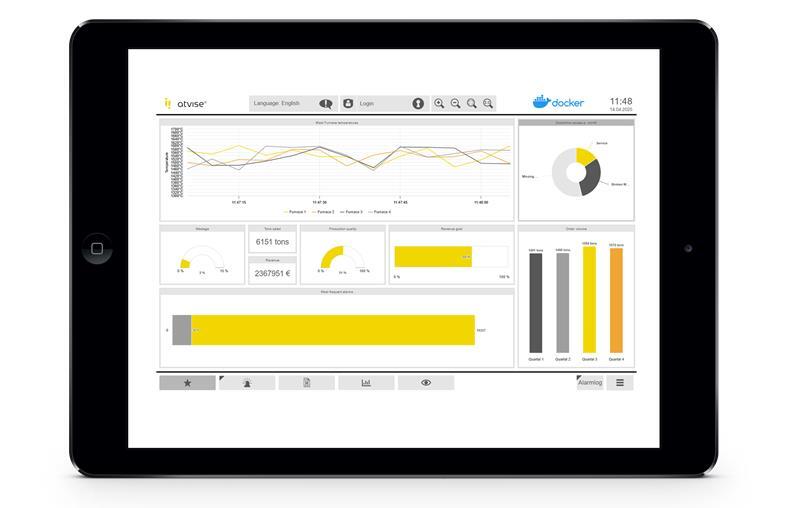

DISCOVER atvise® SCADA

atvise® SCADA is adaptable to any type of industry and sector, allowing you to run live reports and visualize past actions and future actions through the predictive capacity system that it implements in its core.

Fieldbus is a control interface for various devices within a system. The fieldbus uses communication messages as a basis for exchanging information between various devices. So far, there are two types: the standard fieldbus and the industrial fieldbus.

For an HMI system to be used to control a machine, that machine should communicate with the fieldbus. In the past, this was achieved by installing a communications card on the PC or machine. Using an adapter, it was connected to the fieldbus.

However, it is now possible that the serial and Ethernet ports on the PC or machine are capable of handling fieldbus. In this case, the adapter can be removed, and the machine can send and receive fieldbus communication messages via the serial or Ethernet port of the PC or machine.

Types of HMI or Human Machine Interfaces

Human Machine Interfaces can be presented in different formats, from screens on machines and computer monitors, to touch screens and smart devices. Regardless of its format or the terms used to refer to them, its purpose is to provide information about the machine, its production development and performance processes.

Received information from the machines is divided into two main classes: statistical information and control information. These two types of information can be synthesized into a single, supervisory information, which collects statistical and control information and provides a global view of the system.

Monitoring screens

Monitoring screens used for Human Machine Interfaces are systems that recognize the programming language of the machine and provide a graphical representation of it.

You can get a graphical representation of the machine and control its operation through programming commands by using a monitoring screen.

There are a wide variety of HMI interfaces that allow control of the machine from a screen, which can be from a computer or a mobile device. The main ones used in the sector are touch screens and remote access terminals (TAR).

Touch screens

They are screens that present information through direct interaction with the user, that is, user touches the screen to select the menu, buttons, etc. The use of these accessories has been increasing in recent years, due to the great development of computer systems, in addition their use is very comfortable and effective.

Remote Access Terminals (TAR)

They are computer terminals that allow remote connections to a local area network (LAN), so that a user can access the network from wherever they are.

These interfaces are widely used in controlling processes of industrial projects, since they allow access to machines from anywhere in the network. These tools are called data communications or communication tools, which are intended to allow communication between machine and person.

Advantages and benefits of an HMI (Human-Machine Interface) system

The HMI, as we have mentioned before, is responsible for presenting in an easy-to-understand way the necessary information for the optimal operation of a machine, for example: temperature of a process in a factory, pressure of some pumps, amount of energy consumed in an installation, etc.

The HMI system facilitates access to machine control by a human being, who can control the machine easily, quickly and safely.

Unlike other systems, the HMI system offers the advantage of accessing the machine information simultaneously from several locations, for example from a different machine control stations.

Easy and safe access to machine control

HMI systems allow operators to know the information of the different parts of the machine, i.e. indicators, machine status, etc.

Ease of use of HMI systems

One of the main benefits of HMI systems is that users do not need specialized training to be able to properly operate the machine through the system.

Communication between machine and operator

An HMI system is an interface between the user and the machine, which allows communication between both through a tactile graphic interface such as tablets, smartphones, or a fixed station next to the machine.

Machine Information Management

Thanks to the HMI it is possible to obtain the machine information in real time and perform specific operations with this data.

Through the control process and communication between the machine and the operator, the HMI system allows the operator to perform optimal machine management.

Applications of HMI systems in today’s industry

HMI systems are used for industrial machines visualization and control, industrial processes monitoring, facilities management, industrial systems control, etc.

HMI System Applications

An example of application of HMI system can be seen in natural gas processing plants, where the HMI system is responsible for controlling and managing the distribution of natural gas, from the acquisition of the raw material to the sale of the final product. Some of the applications of current HMI systems are:

Temperature control

For temperature control, PID (Proportional, Integral, Derivative) control techniques and other methods are used. HMI systems can help users keep the temperature controlled, indicating to the user the basic parameters of temperature set points, such as: temperature reference value, temperature difference, temperature adjustment speed, etc.

Level control

Level control is carried out by measuring the liquid height. And it can be measured by various methods and techniques, such as ultrasonic level measurement, fiber optic level measurement, etc.

In the case of fiber optic level measurement, the HMI system allows to operate with great ease and comfort. HMI system allows users to know the liquid level, level difference, level adjustment speed, etc.

Pressure control

Pressure control is carried out by measuring the pressure of a system. And it can be measured by various methods, such as ultrasonic pressure measurement, fiber optic pressure measurement, etc.

In the case of fiber optic pressure measurement, the HMI system allows to operate with great ease and comfort. HMI system allows users to know the system pressure, pressure difference, pressure adjustment speed, etc.

How to correctly choose an HMI System?

Today, an HMI (Human Machine Interface) is a basic element in all industrial production or automation systems and allows processes to be operated and controlled more efficiently and safely. To do this, you should choose an interface that is easy to operate, that solves any security problems optimally and that has a design that avoids distractions.

Development of an HMI must be based on a user interface engineering process, so this development phase should not be overlooked. This will reduce product development time and costs and allow the customer to use the product more efficiently from the start.

When developing an industrial control system, user interface engineering process may include the following steps:

- Define user’s needs.

- Analyze requirements.

- Design the user interface structure.

- Design the look and feel of the user interface.

- Implement the user interface.

In addition, a good HMI requires a good structure that meets all the user needs. For example, an HMI may have a TFT panel to display data, a keypad to enter data and directions, a data display screen, an alarm display screen, a status display screen, and a product configuration display screen.

Phases to choose an HMI system without rushing

Phase 1: User Interface Design

The design of a user interface, in which aspects such as ergonomics, functionality, aesthetics and technology must be considered, can be a complex process, which requires understanding functionality, ergonomics and presentation in one piece. It is a complex task, but not impossible, and you must plan the development phases well.

Phase 2: Study of the structure

In the second phase of the user interface engineering process, a study is necessary to define the structure of the user interface. This aspect must be planned carefully; It is important to take into consideration all aspects of the industrial control system. For example, consideration should be given to how maintenance can be carried out more efficiently, how information should be transmitted optimally, and how product configuration information should be provided.

Phase 3: Interface appearance

In the third phase of the UI engineering process, you must design the appearance of the user interface. For example, the TFT panel should include a preview image of each zone and a location indicator for each zone. You should consider how the data can be displayed clearly and usefully.

Phase 4: Implementing the interface

The fourth phase of the UI engineering process is the implementation. This phase requires a search for the best way to present the data and functions of the user interface. For example, consider how data should be stored more efficiently and how it should be presented optimally.

HMI System or SCADA System: Which One to Choose?

While an HMI system is oriented to the monitoring and control of a particular machine, through a graphical interface such as a touch screen or a Panel PC, a SCADA software is a higher-level system with the same performance as an HMI but oriented to an entire infrastructure, not just a machine. In addition to monitoring and control, a SCADA system offers other applications to have a global vision of all facilities and make better decisions regarding production: alarm management, historization or data logging in databases, reports, integration with other industrial and management systems, and much more.

On the other hand, it is very common to confuse an HMI with a SCADA client. In fact, in many projects HMIs are exactly SCADA monitoring and control clients, located next to each machine throughout the entire infrastructure. While it is true that the concepts can overlap, the main difference is that the HMI is a self-contained system, while SCADA clients depend on the SCADA server located elsewhere in the plant network. If the server goes down or if communication between clients and the server is lost, the visualization and control applications on the clients stop working.

How to choose the ideal HMI?

So, which one is best suited for your project? The most common is to have both systems, although essentially it depends on the communications architecture, the budget, the quality of the networks, the criticality of each machine and the need to standardize the visualization, among other variables.

Do you want us to help you choose with no commitment? At atvise® we are specialists in automation of industrial processes with HMI and SCADA systems, which will allow you to increase the performance, productivity, and efficiency of all your industrial processes. What are you waiting for to start automating your manufacturing processes?

How to implement an HMI system?

As we have seen above, an HMI system is a very powerful tool for the organization and optimization of work within the industry. These systems can be implemented in various ways: through a closed or commercial system, or by developing a custom one.

On the one hand, you can opt for the implementation of a customized HMI system. In this case, a team of experts in the area will develop a customized man-machine system tailored to the needs of the company.

On the other hand, you can also opt for the purchase of a commercial HMI system. In this case, the company will select an HMI system from a company specialized in the development of this type of products.

If we want to opt for a closed system, it is very important to check the compatibility with the hardware that we will require for the operation of our HMI system.

In any case, it is important to keep in mind that the implementation of an HMI system requires proper planning. It is important to determine what functionalities are needed and what type of software and hardware best suits the company’s processes.

Steps to follow to implement an HMI System (Human Machine Interface)

At atvise®, as experts in automation of industrial processes and HMI systems, we recommend that you follow a series of steps for the implementation of your human-machine interface in your company:

- The first thing you should do is determine the information about your business that should be displayed on the screen. What data do you need to display? How do you want this data to be displayed? What features do you need?

- Once you are clear about the information to display, it’s time to select the right hardware. We recommend that you explore very well the existing alternatives in the market before opting for a customized system.

- After selecting the hardware, it is necessary to configure it according to the production processes of your company.

- Once the software is set up, it’s time to install it on the computers you need. atvise® HMI SCADA offers you a quick and easy installation, so you can start using the human-machine interface software in minutes.

- Finally, it is necessary to perform a test of the software to make sure that everything works correctly. At atvise®, we offer you a free trial of our HMI SCADA software, so you can see for yourself its operation and versatility compared to other systems on the market.

One of the points that is usually omitted is the training of personnel, since it is often understood that an implementation of a system such as HMI will facilitate the work, but it is necessary to teach the employee to get the most out of it. For this reason, it is very important to have a system where the learning curve is very short and fast as the atvise® HMI SCADA system.