How to program an industrial robot?

Inside of an industrial plant, one of the most important and used elements, especially in the industry 4.0, is the industrial robot. In this article, we will explain how an industrial robot works and how to program it to get the most out of your plant.

What the Industrial Internet of Things seeks is to increase the efficiency of all industrial and manufacturing processes.

What is an industrial robot?

Before getting into the subject, it is important to define what an industrial robot is. An industrial robot is a programmable multifunctional manipulator that has the capacity to move, handle heavy loads in different trajectories or perform various tasks. They usually have 3 or more axes to articulate and develop the function with which they have been programmed.

Basic knowledge to program an industrial robot

As expected, in order to program an industrial robot it is necessary that we master certain programming languages that allow us to send orders to the robot.

The most used language in robotics is C++, but it is not unique one, we can also program our robots with Python and others.

Different methods to program an industrial robot

We must send a binary code (0 and 1) order to the robot to make some movement, but there are different languages that allow us to simplify this process.

There are different technologies for programming an industrial robot, always depending on the robot itself, but the most used is the Teach Pendant Interface.

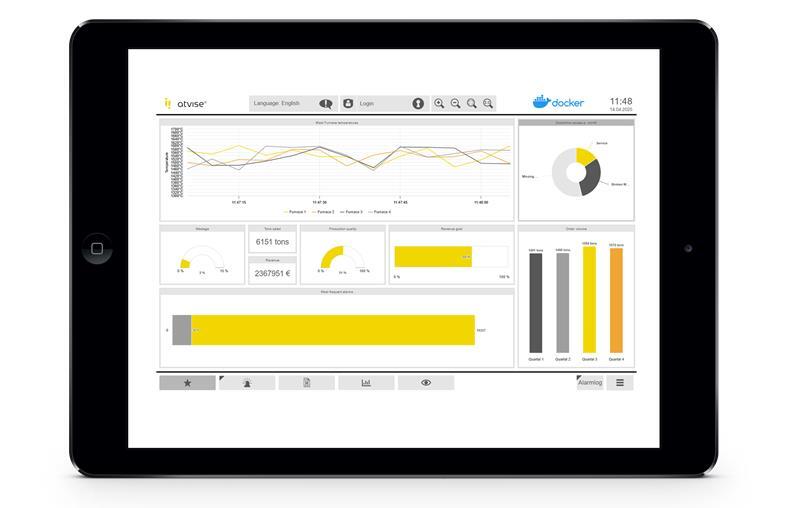

DISCOVER atvise® SCADA

atvise® SCADA is adaptable to any type of industry and sector, allowing you to run live reports and visualize past actions and future actions through the predictive capacity system that it implements in its core.

Teach Pendant Interface

It is the most used to program industrial robots since we can find it in 90% of robots or manipulators according to the British Automation & Robot Association (BARA).

Tech Pendant is an updated technology that has been able to tailor the market needs. Currently they can even be programmed from a Tablet.

To program the industrial robot, the worker or operator must perform each of the movements that we want the machine to perform autonomously once we save the coding. For this, it is necessary to know how to use its specific interface, since the movements that the robot must perform later have to be very precise.

Conclusions on how to program your first industrial robot

The benefits of a properly programmed robot are quite a few, but the main one is to be able to integrate the robot into your SCADA system and automate all the processes of your industrial plant.

At atvise® we are specialists in automation of industrial processes with the SCADA system that will allow you to increase the performance, productivity and efficiency of all your industrial processes. What are you waiting for to start automating your manufacturing processes?