IIoT: The Internet of Things in the Industrial sector

The hyperconnectivity to which we submit every day makes it easier to understand that IoT and Big Data is the gold of the XXI Century. There are already many sectors that have joined the innovation and have incorporated this type of advances in the companies that make them up, and the industrial sector was not going to be left behind.

IIoT: What is it and what does it mean?

To define Industrial IoT (IIoT) we will refer to the definition provided by the technology manufacturer Cisco:

Industrial Internet of Things (IIoT) is the use of the Internet to connect machines, devices, and enterprise systems through network architecture in a way that allows them to interconnect and communicate with each other. It is a service-based architecture that allows you to know and manage device connections and data remotely and allows users to leverage IoT technology to create new applications and experiences.

The IIoT, or Industrial Internet of Things, is the part of the Internet of Things (IoT) applied to industry. In other words, it is the subset of the Internet of Things that is dedicated exclusively to industrial production. What the Industrial Internet of Things seeks is to increase the efficiency of all industrial and manufacturing processes.

How does the IIoT work and how to implement it?

IIoT began to be implemented in the automotive industry to reduce fuel consumption. That was the first industrial-level application of this type of technology. Today, it still is more of a trend than a reality. For the IIoT to become a reality, technologies need to be robust and reliable.

The goal of the IIoT is to integrate the functions of the different devices, generating a work platform with a unitary vision. Today, the IIoT is a reality in health, to the extent that all clinical information has been integrated into a mobile application.

A good example of IIoT is the one used in the construction industry for cementation quality control. For example, when building a bridge, the quality of cementation can be controlled as sensors measure temperature, pressure, humidity, wind speed and other parameters.

Basic structure of an IIoT system

A basic IIoT structure has several elements that we will mention below, but it can be composed of many more:

- Smart devices: These can be sensors, controllers or any device that are placed in the base and would have the mission of collecting different data, saving all the information, and sending it to the relevant system to be processed.

- Gateway: It is the element that allows the connection between smart devices and the rest of higher elements through different protocols and architectures.

- Local server: Is the software that connects everything and constitutes the IIoT system. In most cases it is from where the user has access.

- Cloud computing: It is where all the data is processed, crossed, and analyzed. This process is done in the cloud to avoid data requests.

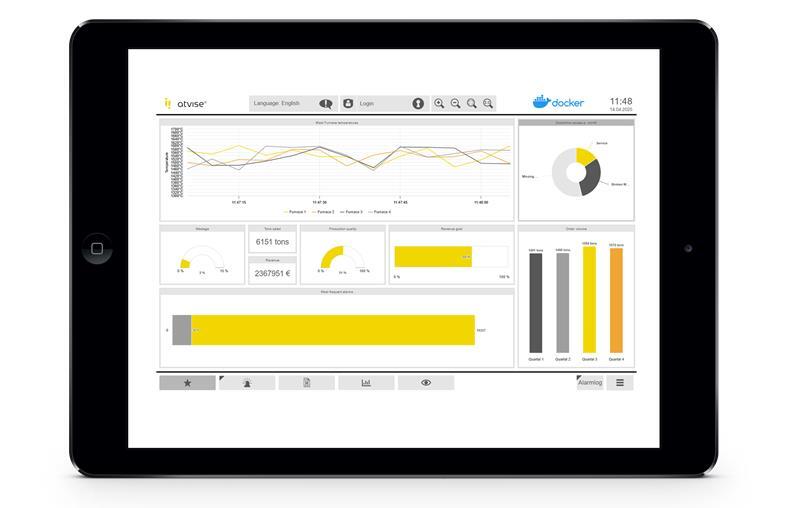

DISCOVER atvise® SCADA

atvise® SCADA is adaptable to any type of industry and sector, allowing you to run live reports and visualize past actions and future actions through the predictive capacity system that it implements in its core.

Advantages of Industrial IoT

Industrial IoT (IIoT) offers a wide range of advantages. Improvements in productivity, reduced operating costs, improved efficiency and increased safety can be made. The main advantages it aims to offer are the following:

- Improve operational efficiency through improving the quality, efficiency and production of products or services.

- Reduce costs by reducing production and maintenance costs on products.

- Improve customer satisfaction by providing new and improved applications for use.

- Reduce risks through early detection of failures and improvement in maintenance management.

The application of these technologies has been a great advance in industry and also in services sector, since through a network of product sensors, their functions can be monitored, managed and optimized, so their safety, quality, efficiency and safety can be increased.

IIoT can help achieve greater productivity and reduce costs by increasing efficiency, and also improve quality by being more agile in responding to customer demands and increasing customer satisfaction.

Benefits of using IIoT in Industry

Like the Internet of Things, the IIoT has many benefits for businesses. The most relevant for the industrial sector are the following:

- Increases energy efficiency: thanks to the possibility of measuring energy consumption in real time, companies can detect where there is an inefficiency and solve it in the most appropriate way to reduce this lack.

- Just-in-time (JIT) production models: having much more data and the possibility of processing it in real time (order management, manufacturing capacity, available personnel, etc.), allows companies to set more efficient and realistic production systems.

- Improves machinery maintenance: It is one of the most important benefits for companies, since costs of not performing maintenance correctly or not detecting a failure in the machine in time can be several thousand euros, either due to the machine cost or loss of productive capacity.

- Increases industrial safety: Through an IIoT system we will monitor all the important data related to the computer security of our company and the safety and health of our workers; since, for example, if a smoke or gas extraction valve fails, we will receive a real-time alert.

Would you like to know more about how you can improve the efficiency of your industrial company thanks to the IIoT? We are experts on solutions and automations applied to the industrial sector, do not hesitate to contact us!