Learn about industrial automation processes

Nowadays, having a production plant without automated systems is inconceivable for most sectors. For this reason, we want to explain in depth what the automation of industrial machinery consists of and the process to implement it in your factory

Automation of Industrial Machinery at present

Automation process of Industrial Machinery is one of the most important technologies from a selling costs point of view in a company, as it aims to reduce labor and increase productivity and consequently, profitability. Some sectors of automotive industry, chemical industry, textile industry, metallurgic industry and food & beverage industry have considerably grown in their productivity due to automation of their industrial machinery.

In the case of the automotive industry, the machinery automation rate is as of 80%. Vehicle factories have been greatly modernized and have achieved an increase in productivity.

What is Industrial Machinery Automation?

Automation of Industrial Machinery is the technology that allows the automation of controlling functions of industrial machines involved in plant processes. It is a highly specialized technology and requires specialized equipment and a high degree of technological knowledge.

Industrial machinery automation is a type of technology that is used to control a wide range of processes that include aspects such as:

- Programmable controllers or PLC’s

- Communication networks

- Monitoring system

- Maintenance and repair

- Systems Architecture

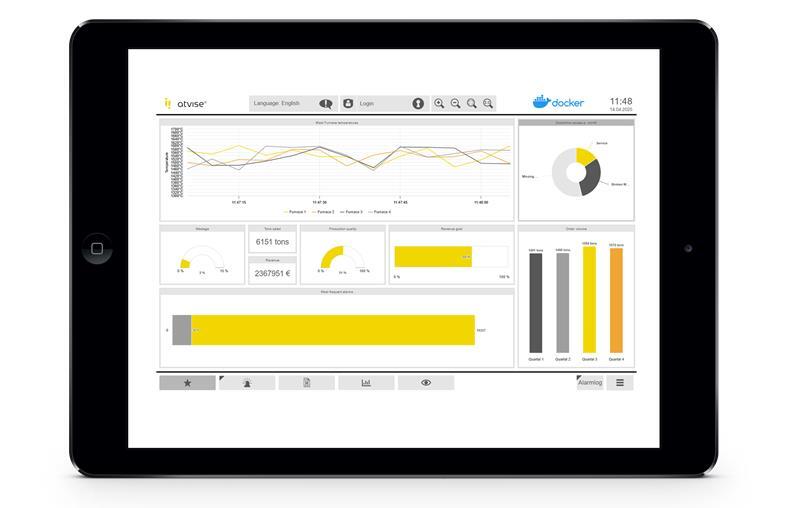

DISCOVER atvise® SCADA

atvise® SCADA is adaptable to any type of industry and sector, allowing you to run live reports and visualize past actions and future actions through the predictive capacity system that it implements in its core.

Applying Industrial Automation: How to Do It?

There are generic solutions that require some customization to fit the manufacturing and production conditions of each company. Either way, there are several steps to follow to properly implement an automated industrial machinery system:

Study to determine if this technology is feasible in your factory

The industrial machinery automation company must have extensive experience and knowledge in the process to develop a technical proposal, as well as working with the latest systems on the market.

Technical proposal evaluation

In this step, an engineering team must evaluate the ability of the automation company to carry out the automation of industrial machinery project.

Service contract drafting

Service contract is a legal document that formalizes the obligations of the involved parties. Service contract should include a detailed plan of machinery automation and final product specifications.

Prototype development

A prototype is a sample that allows the company to evaluate the used technology for the industrial machinery automation. At this point, it is very important that everything works according to the production and manufacturing needs of the company, as an error can indicate an extra cost at the end of the implementation process.

Industrial machinery production start-up

An engineering team specialized in industrial machinery automation must deliver the industrial machinery and train the company’s stuff to properly use the new implemented systems.

Maintenance and repair of industrial machinery

The responsible automation services company must perform the maintenance and repair of industrial machinery. Maintenance and repair process of industrial machinery must be transparent and defined in the service contract.

At atvise® we are specialists in SCADA systems for the industry 4.0, which will allow you to control your industrial processes and increase performance, productivity and efficiency of your factory. What are you waiting for to join the technological opportunities of the new industrial revolution?