What is OPC UA Protocol?

The Unified Open Platform Communications Architecture (OPC UA) is a communication protocol between machines that allows information and data to be exchanged between one machine and another in a simplified way.

While classic OPC protocol could cause vulnerability failures in some scenarios (by using random ports through Firewalls between machines), the new version with unified architecture resolves this conflict and provides greater compatibility.

Traditionally, with classic OPCs, it was normal to limit ourselves to build communications only between SCADA systems and PLCs. While with OPC UA, we can send data to any type of system (ERPs, Excel sheets, mobile applications, etc.) in a simpler and more secure way.

Differences between OPC UA and conventional OPC

| OPC UA | Classic OPC | |

Operating system |

Any operating system, be it Android, Linux or Windows | Windows Technology (COM/DCOM) |

Security |

Communication encryption through digital certificates | Unencrypted communications |

Technology |

It can be installed on a machine or can be embedded in PLCs | It must be installed on a machine |

Information model |

It combines all of them in a single technology | Different technologies to deal with each type of data source and not all of them can communicate with each other |

Firewall |

Very simple to set up | In case of communication between machines through Firewall, very complex to configure and at the same time presents vulnerabilities |

OPC UA: Benefits of industry

Thanks to the improvements applied to the classic OPC, OPC UA allows to improve the communication between all the active systems in our industrial plant. Not only machine-to-machine (M2M) communication, but also in the processing of data focused on the IoT.

In addition, OPC UA communication protocol allows small companies without a large budget to incorporate it and approach industry 4.0, as it reduces the costs of system integration.

With all these improvements, a leap has been made towards a much more efficient automation and much easier to implement.

Benefits of integrating OPC UA and SCADA

As we have seen, integrating a system using OPC UA protocols has many more benefits than a system with classic OPC. All these advantages are maximized when we connect our OPC systems with SCADA.

The main advantages of OPC UA and SCADA integration are:

Increased reliability and security

OPC UA is oriented to communications over TCP / IP compatible with the security provided by Firewalls. This allows OPC UA servers and SCADA systems to be separated in different machines, providing greater reliability and security to the infrastructure.

Increased performance

OPC UA with SCADA integration also brings greater interoperability. OPC UA has become the communications standard for Industry 4.0, so all control systems and software applications tend to incorporate it into their stack. This means higher performance in all systems, especially in SCADA, where much more data can now be integrated and more valuable information can be obtained for decision making.

Increased efficiency

Being an increasingly integrated standard and accepted by all manufacturers, system integration is practically straightforward. Beyond the security provided by this protocol, today it is much faster and more efficient to integrate systems with each other through OPC UA than through classic OPC or other protocols. Therefore, OPC UA directly implies a saving of time and costs in integration.

Greater flexibility

Trends towards standardization of industrial communications through OPC UA also implies flexibility. Many machinery manufacturers, instrumentation, PLCs and other devices are integrating OPC UA as a standard communications protocol. This means that they can be integrated “plug and play” with SCADA systems, especially with those whose native protocol is OPC UA, as is the case with atvise® software.

Greater interoperability

And in addition to industrial field devices, control systems and PLCs, also higher level software applications are incorporating OPC UA as a communications protocol: MES/MOM systems, ERP platforms, CMMS systems, alarm management and notification software, and more. OPC UA stands for full interoperability in industrial communications.

Greater scalability

All of the above also implies greater scalability. As communications over any network are feasible and secure, and as they are increasingly available on more systems and devices, OPC UA communications infrastructures can be scaled as production grows without any limitation.

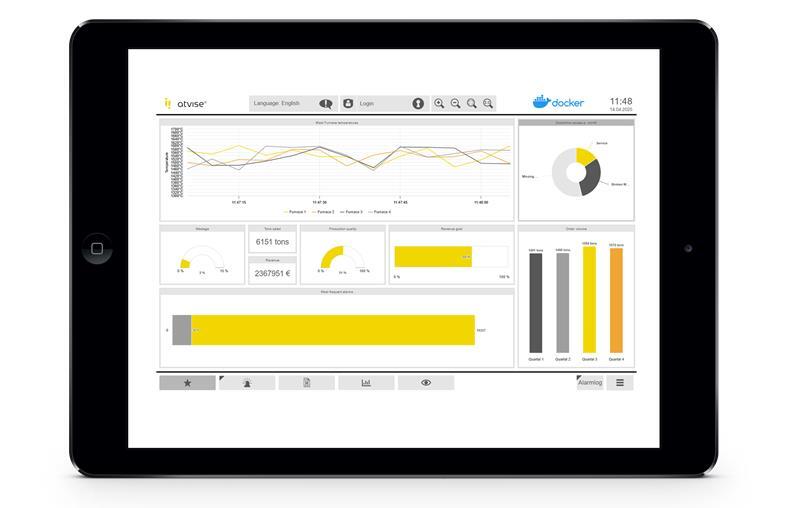

DISCOVER atvise® SCADA

atvise® SCADA is adaptable to any type of industry and sector, allowing you to run live reports and visualize past actions and future actions through the predictive capacity system that it implements in its core.

What alternatives does exist to OPC UA protocol?

Currently on the market there are few alternatives to this communication protocol. The most widespread are classic OPC protocol, based on Windows COM and DCOM objects, which with the appearance of OPC UA is becoming obsolete, and MQTT protocol.

In this second case, more than an alternative, it could be said that it is a complement. Summarizing it a lot and leaving information pending to be extended, it could be said that OPC UA is oriented to “heavy” industrial communications (data with alarms, metadata, historization, formats, structures, instances and others) while MQTT is oriented to light communications, justifying itself very well when networks between the systems to be connected are very weak, very remote or when there is charge for traffic. In any case, there are platforms such as vNode Automation that facilitate hybrid OPC UA and MQTT systems.

How and when should we change the M2M communication protocol?

To make any software change, you must be very clear about the target you intend to achieve. In case of OPC, we should see what the current level of integration is in our plant, if the communication between systems is optimal and if it would be feasible for us to scale the production model with the current system.

The differential factor that should help you decide if OPC UA is for your production plant is, without a doubt, if we seek to automate long-term processes without losing information along the way and avoiding errors.

Performing a change implementation from OPC to OPC UA is not an easy task, as there are many elements to consider and it must be tailored to the plant in which it is going to be integrated.

With atvise® SCADA, you don’t have to worry about the interoperability of your HMI SCADA with the rest of your plant’s industrial systems, as it is software entirely based on OPC UA. Contact us for more information!