The combination of SCADA systems with Artificial Intelligence (AI) is no longer a futuristic promise—it is an increasingly present reality in industrial environments. Today, the most competitive companies are already leveraging this fusion to optimize processes, anticipate failures, and make smarter decisions, all in real time.

How Do SCADA and Artificial Intelligence Work Together?

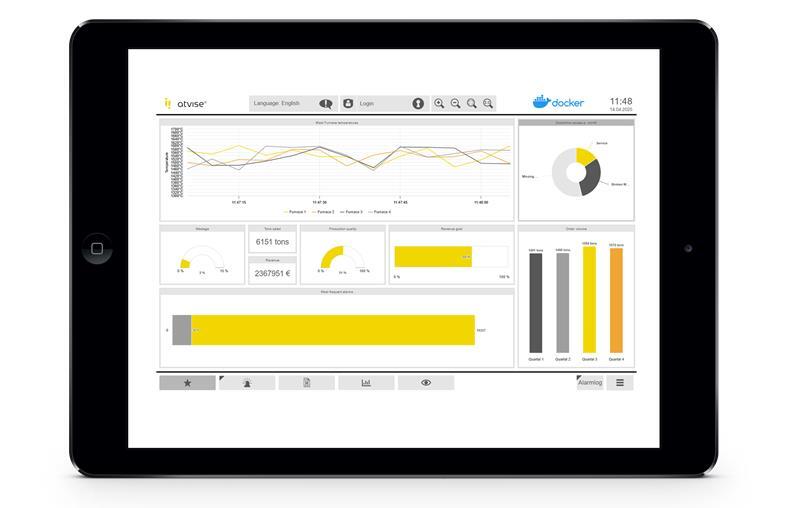

A modern SCADA system like atvise® allows real-time data collection from multiple sources (PLCs, sensors, databases, MES systems, etc.), centralized visualization, and event and alarm generation.

AI, on the other hand, provides the ability to analyze large volumes of data, detect complex patterns, predict future behaviors, and automate decision-making. The fusion of both technologies creates an ecosystem where data is not just displayed—it is interpreted and transformed into action.

Recent Advances in SCADA + AI

🔹 More Accessible AI Models:

You no longer need a team of data scientists to implement AI solutions. Platforms like TensorFlow, RapidMiner, or even natural language-based intelligent assistants allow predictive models to be integrated with ease.

🔹 Edge Inference:

More and more factories are using edge devices (IPCs, industrial gateways) to run AI models directly on-site, reducing reliance on the cloud and improving latency and security.

🔹 Interaction with Generative AI:

LLMs (Large Language Models) are already being used in some facilities to interpret incident logs, draft automated reports, or generate queries on SCADA databases using natural language.

🔹 Open Integrations:

atvise® SCADA stands out thanks to its open-standard architecture—OPC UA, web services, and JavaScript scripting—making it easy to integrate with external Python environments, REST APIs, databases, or tools like Node-RED.

💬 “The key is not the scripting language, but having an open architecture that allows integration with AI models developed in purpose-built environments, such as Python or other specialized platforms.”

DISCOVER atvise® SCADA

atvise® is an industrial software platform developed with open standards such as OPC UA and pure web technology, enabling the integration and design of advanced applications for visualization, control, and data analysis.

Types of Artificial Intelligence Applied to Industry

AI plays a key role in the digital transformation of the industrial sector, optimizing processes, reducing costs, and enhancing decision-making. Below are the main AI approaches and how they are currently applied in industrial environments:

| AI Type | Industrial Application | Description |

| Supervised Learning | Quality control, visual inspection, product classification | Algorithms are trained on labeled data to detect defects, classify parts, or predict results based on process variables. |

| Unsupervised Learning | Anomaly detection, data segmentation, predictive maintenance | Discovers hidden patterns in large datasets without the need for labels. Useful for identifying emerging failures or unusual behaviors. |

| Reinforcement Learning | Process optimization, adaptive control, industrial robotics | The system learns through trial and error, maximizing a reward. Used in complex tasks such as dynamic setpoint adjustment or robot control. |

| Natural Language Processing (NLP) | Report automation, alarm interpretation, virtual assistance | Enables machines to understand and interpret human language. Used in industry for generating reports, analyzing documentation, or interacting with operators. |

| Computer Vision | Visual inspection, traceability, defect detection | Interprets images or video in real time. Helps verify product quality, read labels, or track items on a production line. |

| Neural Networks and Deep Learning | Demand forecasting, advanced maintenance, multivariable classification | Complex models that detect non-linear relationships. Used to analyze large volumes of data and forecast future conditions or outcomes. |

| Expert Systems | Fault diagnosis, decision support | Mimic human reasoning through rules. Assist in diagnosing equipment issues or suggesting corrective actions based on prior experience. |

| AIoT (AI + IoT) | Real-time monitoring, asset analytics | Combines connected devices with AI algorithms. Sensor data is analyzed to predict failures or enhance operational performance. |

Advanced AI Applications in SCADA Environments

Predictive Domain

The combination of SCADA with Machine Learning and predictive analytics algorithms enables much greater precision in anticipating mechanical, electrical, or operational failures. By jointly analyzing historical and real-time data, models can detect wear patterns or anomalies before they become critical issues.

This enables predictive maintenance, reducing downtime, optimizing resource planning, and extending the useful life of industrial assets.

Smart Automation

Next-generation SCADA systems, integrated with machine learning algorithms, can automatically adjust process parameters based on operational context: demand, environmental conditions, energy efficiency, etc.

This adaptive automation improves efficiency, reduces waste, and enables real-time response to unexpected changes. Additionally, models can learn from their own decisions using reinforcement learning.

Cybersecurity in SCADA Systems with AI

AI provides an active defense through algorithms that detect suspicious behavior patterns. Communications, access logs, and system data are continuously monitored to identify cyber threats early.

Over time, learning models enhance the system’s security posture, especially in critical infrastructure environments.

Intelligent User Interface

Modern SCADA interfaces integrated with AI offer:

– Context-aware, adaptive visualizations

– Smart recommendations in response to events or anomalies

– Automated reports generated in natural language

– Virtual assistants to support operators in real time

All of this streamlines decision-making, reduces human error, and enhances operational efficiency.

How Does atvise® SCADA Make It Possible?

Thanks to its 100% open-standards approach and native OPC UA server, atvise® SCADA enables the development of intelligent solutions without being limited by proprietary languages or closed architectures. Data can be easily published and consumed by AI engines, making atvise® a solid foundation for future-ready industrial projects.

Its HTML5 web interface also allows users to visualize AI-generated results (recommendations, smart alerts, dynamic charts) in real time and from any device.

What Do You Need to Get Started?

- An open SCADA platform, like atvise®

- Historical and real-time data

- A trained AI model (or a platform to help you build it)

- A clear integration and evaluation strategy

AI is not here to replace SCADA, but to enhance it. In this new paradigm, the human operator remains essential—now supported by powerful tools that help understand what is happening, why, and what to do about it.

Are you ready to take your SCADA system to the next level?