Have you ever wondered how large industries manage to monitor and control their most complex operations with precision and efficiency? The answer lies in an essential tool for Industry 4.0: SCADA software. This system not only optimizes processes but also improves real-time decision-making.

In this article, we will explain what SCADA is, how it works, and why its implementation is a strategic decision for any industry seeking to remain competitive.

What is SCADA software?

The term SCADA stands for “Supervisory Control and Data Acquisition.” It is a computer system designed to monitor, supervise, and control industrial processes in real-time. These processes range from machinery management in production plants to the operation of energy, water, and transportation systems.

SCADA software collects data through connected sensors and devices, processes this information, and presents it in intuitive graphical interfaces. This allows operators to make data-driven decisions, optimizing operations and anticipating potential issues before they become critical failures.

In short, this type of application is the digital brain that ensures industrial operations remain under control.

How does a SCADA system work?

The operation of a SCADA system is based on an architecture that connects sensors, controllers, and software to provide real-time supervision. This process can be divided into several stages:

- Data collection: Sensors placed at strategic points within a facility gather key information, such as temperature, pressure, speed, or production levels. These sensors are designed to measure specific variables according to the needs of each industry.

- Data transmission: The data collected by the sensors is sent to programmable logic controllers (PLCs) or remote terminal units (RTUs). These devices act as intermediaries, communicating with the SCADA software.

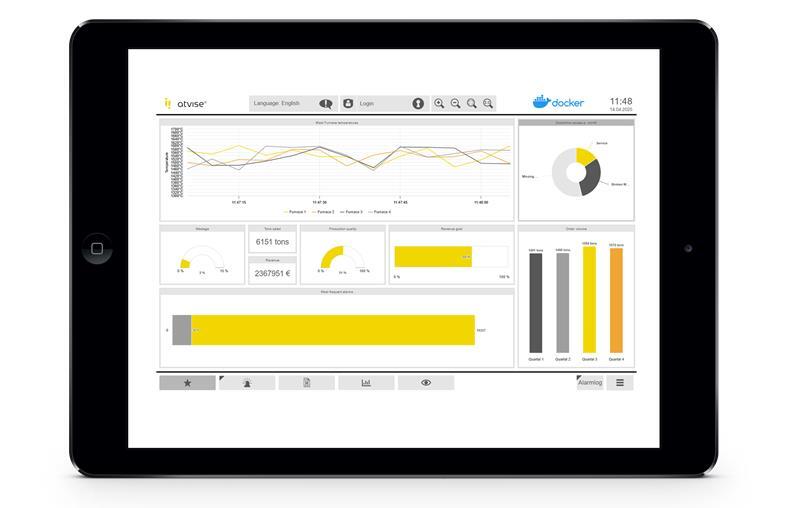

- Processing and visualization: The software interprets the transmitted data and converts it into visually comprehensible information for operators. This visualization may include graphs, diagrams, and alarms that display the real-time status of processes.

- Control and supervision: Operators can use the SCADA system to adjust parameters, activate alarms, or implement automation as needed. In many cases, the system also includes algorithms that allow automatic responses to certain events.

The ultimate goal of SCADA software is to ensure that all processes operate safely, efficiently, and without interruptions.

Advantages of SCADA software in modern industry

In an increasingly competitive environment, implementing a SCADA system provides significant advantages for businesses. This software enables:

- Real-time monitoring: Gain a complete view of process and equipment status at any time.

- Failure prevention: Detect potential issues before they turn into failures that affect production.

- Resource optimization: Identify inefficiencies and optimize the use of energy, raw materials, and time.

- Smart automation: Reduce the need for manual intervention, minimizing the risk of human errors.

- Scalability and flexibility: Adapt to new operational demands or integrate emerging technologies like the Internet of Things (IoT).

These features make SCADA software an essential tool for industries such as manufacturing, energy generation, water treatment, and logistics.

atvise® SCADA solution: Technology at the service of industry

The SCADA concept of atvise® goes beyond the conventional. Our approach focuses on providing fully customized solutions tailored to the demands of Industry 4.0.

What makes atvise® different?

- Native Web SCADA: Our technology enables visualization and control directly from any web browser, eliminating the need to install additional software. This ensures accessibility from any device, whether a computer, tablet, or mobile phone.

- OPC UA Protocol: This communication standard ensures secure and reliable interoperability between devices and systems, regardless of the manufacturer.

- 100% Online SCADA Engineering: Design, configure, and update your SCADA system remotely. This capability not only reduces implementation times but also lowers operational costs.

- Multiplatform: Our solution is fully compatible with major operating systems, making it ideal for environments with technological diversity.

- Advanced Data Analysis: Our library of intelligent graphical objects, with an alert and maintenance management system, along with our library of advanced dashboards, provides users with unprecedented reliability when making both process and business decisions.

Thanks to these features, atvise® is not just another SCADA software on the market but a strategic tool to transform your operations and take them to the next level.

Why choose SCADA software today?

The shift towards digitization and automation in the industry is not a passing trend; it is a necessity to stay competitive in a global environment. A well-implemented SCADA system not only ensures more efficient processes but also provides the ability to anticipate future needs.

With atvise®, you are choosing a reliable, innovative solution fully aligned with the demands of modern industry. If you seek to maximize productivity, efficiency, and operational quality, we are here to help.

Discover more about our solutions by visiting our website.